Events & Promotions

|

|

GMAT Club Daily Prep

Thank you for using the timer - this advanced tool can estimate your performance and suggest more practice questions. We have subscribed you to Daily Prep Questions via email.

Customized

for You

Track

Your Progress

Practice

Pays

Not interested in getting valuable practice questions and articles delivered to your email? No problem, unsubscribe here.

- Nov 20

07:30 AM PST

-08:30 AM PST

Learn what truly sets the UC Riverside MBA apart and how it helps in your professional growth - Nov 22

11:00 AM IST

-01:00 PM IST

Do RC/MSR passages scare you? e-GMAT is conducting a masterclass to help you learn – Learn effective reading strategies Tackle difficult RC & MSR with confidence Excel in timed test environment - Nov 23

11:00 AM IST

-01:00 PM IST

Attend this free GMAT Algebra Webinar and learn how to master the most challenging Inequalities and Absolute Value problems with ease. - Nov 25

10:00 AM EST

-11:00 AM EST

Prefer video-based learning? The Target Test Prep OnDemand course is a one-of-a-kind video masterclass featuring 400 hours of lecture-style teaching by Scott Woodbury-Stewart, founder of Target Test Prep and one of the most accomplished GMAT instructors.

Kudos

Bookmarks

Dropdown 1: 9

Dropdown 2: June

Be sure to select an answer first to save it in the Error Log before revealing the correct answer (OA)!

Difficulty:

35%

(medium)

35%

(medium)

Question Stats:

75% (02:10) correct 25%

(02:07)

wrong

25%

(02:07)

wrong  based on 373

sessions

based on 373

sessions

History

Date

Time

Result

Not Attempted Yet

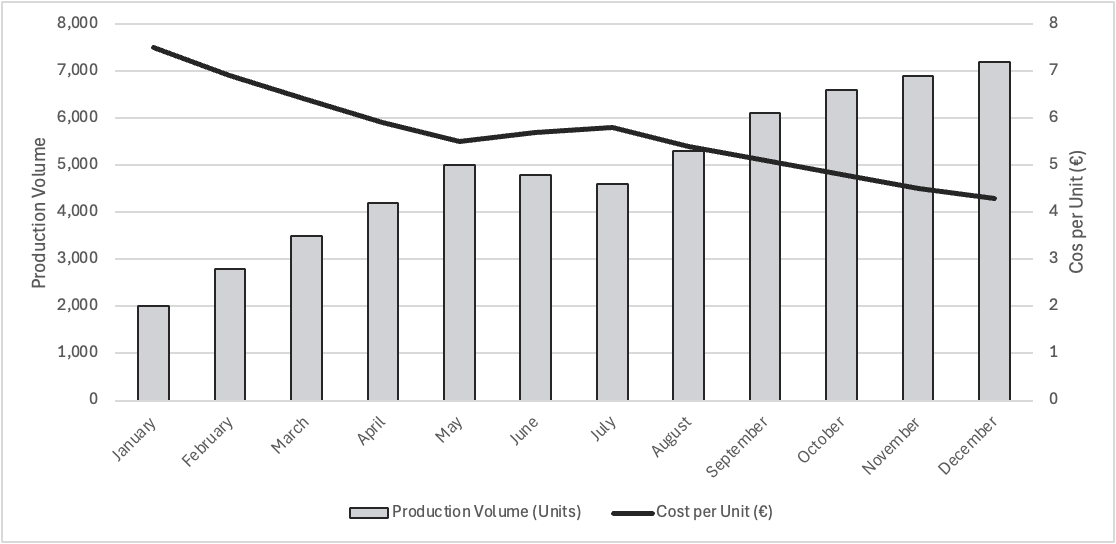

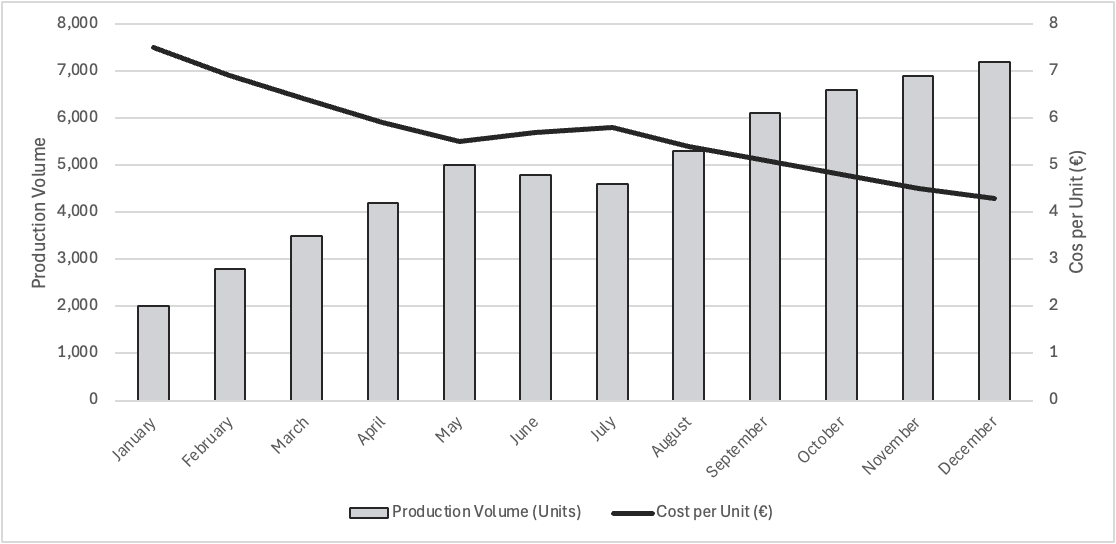

The graph above displays data from a manufacturer’s operations over a 12-month period.

The bar chart shows the total production volume (in units) for each month (measured on the left vertical axis), while the line graph shows the corresponding cost per unit (in euros, measured on the right vertical axis).

An operations analyst defines:

Based on the information in the graph:

The number of month-to-month intervals during which the company demonstrates economies of scale is and the first month in which the company demonstrates an inefficiency event is

GMAT-Club-Forum-pu8acq4f.png [ 40.08 KiB | Viewed 2014 times ]

The bar chart shows the total production volume (in units) for each month (measured on the left vertical axis), while the line graph shows the corresponding cost per unit (in euros, measured on the right vertical axis).

An operations analyst defines:

- Economies of scale as any month-to-month period during which production increases while cost per unit decreases. For eg. if production increases from March to April, and correspondingly, cost per unit decreases, that counts as 1 month-to-month period.

- An inefficiency event as any month-to-month period during which production decreases while cost per unit increases.

Based on the information in the graph:

The number of month-to-month intervals during which the company demonstrates economies of scale is and the first month in which the company demonstrates an inefficiency event is

Attachment:

GMAT-Club-Forum-pu8acq4f.png [ 40.08 KiB | Viewed 2014 times ]

ShowHide Answer

Official Answer

Dropdown 1: 9

Dropdown 2: June

Kudos

Bookmarks

The analysis of the Operation Analyst pretty much forms our base for answering the question.

1. There are total 9 Economies of Scale ( Increase in prod whilst a simultaneous decrease in the cost per unit ) namely: Jan-Feb, Feb-Mar, Mar-Apr, Apr-May, Jul-Aug, Aug-Sept, Sept-Oct, Oct-Nov & Nov-Dec. Thus 9 intervals.

2. An inefficiency event (Decrease in Prod and Increase in per unit cost) can be easily observed for months of June & July.

1. There are total 9 Economies of Scale ( Increase in prod whilst a simultaneous decrease in the cost per unit ) namely: Jan-Feb, Feb-Mar, Mar-Apr, Apr-May, Jul-Aug, Aug-Sept, Sept-Oct, Oct-Nov & Nov-Dec. Thus 9 intervals.

2. An inefficiency event (Decrease in Prod and Increase in per unit cost) can be easily observed for months of June & July.

Kudos

Bookmarks

Bunuel

Solution:

Dropdown 1: Number of month-to-month intervals showing economies of scale

An economy of scale occurs when, from one month to the next, production increases and cost per unit decreases.

Visually inspecting the graph, we observe the following intervals meet this condition:

January → February: Bar increases, line decreases

February → March: Bar increases, line decreases

March → April: Bar increases, line decreases

April → May: Bar increases, line decreases

July → August: Bar increases, line decreases

August → September: Bar increases, line decreases

September → October: Bar increases, line decreases

October → November: Bar increases, line decreases

November → December: Bar increases, line decreases

This gives a total of 9 intervals.

Correct answer: 9

Dropdown 2: First month with a production decrease and cost increase

An inefficiency event is defined as a month where production decreases while cost per unit increases.

This pattern first occurs between:

May → June:

Bar decreases slightly → production falls

Line rises → cost per unit increases

This is the first month-to-month period in which both conditions for an inefficiency are satisfied.

Correct answer: June